Introduction to Precision Machining

In contemporary manufacturing, precision machining is a pillar of innovation and quality assurance. It entails transforming raw materials into components that adhere strictly to defined specifications. This high-stakes procedure is essential in sectors like medical devices and aerospace, where the demand for CNC Turning and other machining techniques is ever-increasing. Precision machining enhances product performance and ensures compatibility and safety in applications that demand the utmost reliability.

Moreover, the strategic use of precision in manufacturing goes beyond meeting specifications—it creates a competitive advantage. The commitment to excellence here ensures that parts seamlessly integrate into larger systems, fostering improved functionality. Companies today prioritize understanding why precision matters, recognizing its role in achieving seamless operations and innovative products.

The Role of Precision Tools

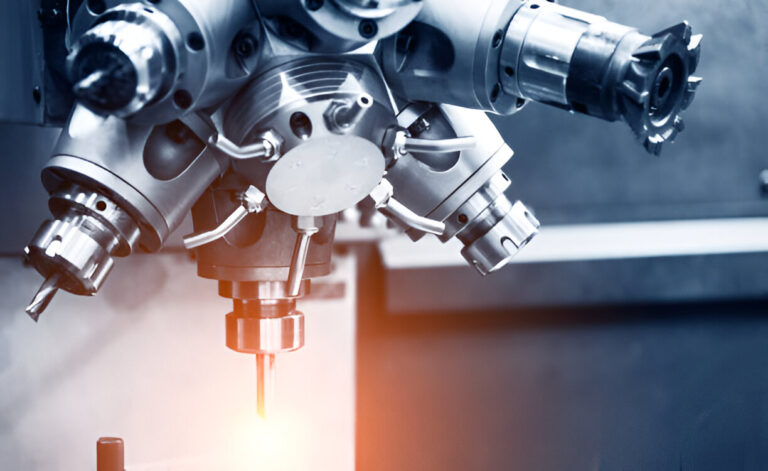

Precision tools are the backbone of the machining process. They include various equipment like lathes, mills, and drills, each designed to perform specific functions on different materials. The selection of these tools is not arbitrary; instead, it is a calculated step informed by the material’s properties and the intended design of the component. For instance, a lathe is often employed to create symmetrical pieces, while milling machines tackle more intricate designs.

The efficiency and precision of machining are directly tied to the quality of these tools. Using state-of-the-art tools reduces the margin for error and increases production speed, directly impacting production costs and timelines. Regular tool assessment and updates are essential to ensure that machining processes remain at peak performance, serving as insurance for maintaining high standards in product quality.

Understanding Material Properties

A thorough understanding of material properties is paramount in precision machining. Each material—metal, plastic, or composite—has challenges and advantages. Metals might provide durability but require careful handling due to their hardness. Plastics, while more flexible, might pose challenges related to thermal expansion during machining.

This understanding aids in selecting the correct machining parameters and tools, reducing the likelihood of errors such as tool wear or component deformation. Proper material analysis is crucial for ensuring quality and optimizing the entire machining process, reducing waste and increasing manufacturing efficiency.

Modern Technologies in Machining

Thanks to technological advancements, the toolbox for precision machining has significantly expanded. CNC (Computer Numerical Control) equipment and CAD (Computer-Aided Design) have been game-changers, offering new levels of precision previously impossible. These technologies make manufacturing processes faster and more reliable, as machines can operate with minimal human interference, drastically reducing the possibility of human error.

Automation and IoT introduce additional layers of sophistication, offering real-time monitoring and predictive maintenance capabilities. Such advancements mean problems can be identified and rectified quickly, minimizing downtime and ensuring consistent production quality. This continual improvement cycle enables producers to investigate uncharted territory regarding product design and production efficiency by speeding up innovation.

Challenges and Solutions in Precision Machining

No manufacturing process is devoid of challenges, and precision machining is no exception. Wear and tear on cutting tools can lead to reduced accuracy, while heat generation during cutting might cause thermal expansion, affecting dimensional accuracy. These challenges require proactive solutions.

Approaches such as utilizing high-quality, wear-resistant tools and implementing effective cooling systems are vital for mitigating these issues. Besides technological solutions, educating operators on the latest machining techniques is equally important. Through continuous training, they can better manage the nuances of precision machining, applying techniques that enhance quality and efficiency.

Tips for Optimizing Machining Processes

For manufacturers keen on optimizing their machining processes, several practical strategies can be instrumental:

- Invest in their regular examination and upgrade to guarantee that machining tools stay at the forefront of technology.

- Establish a strict maintenance program for every piece of equipment to reduce unplanned downtime that could interfere with output.

- Make training and development programs a top priority to give workforce teams the newest information and abilities regarding machining innovations.

Future Trends in Precision Machining

The future of precision machining is gleaming with potential, driven by technological advancements such as additive manufacturing or 3D printing. This development makes creating intricate, personalized components with previously unheard-of precision possible. Smart factories further illustrate future pathways, combining interconnected machinery and advanced data analytics to foster unparalleled operational efficiencies.

Furthermore, incorporating AI and machine learning into manufacturing processes is expected to usher in a new era of innovation. These technologies will likely serialize tasks that once took weeks into processes accomplishable in mere days, enhancing precision and production capabilities.

Conclusion: The Impact of Precision in Manufacturing

Precision machining remains a cornerstone of modern industrial manufacturing, providing the foundation for quality and reliability across various sectors. However, its function always changes as technology opens up new approaches and efficiencies, providing exciting opportunities for the manufacturing industry’s future. Those who embrace and harness these innovations will likely spearhead the next wave of industrial transformation, setting new benchmarks in engineering excellence.

david Miller is an experienced English language expert with a deep passion for helping others communicate effectively and confidently. With a background in linguistics and literature, He provides clear, accessible insights on grammar, writing, and communication strategies. Through well-researched articles and practical advice, David Miller aims to make language learning both inspiring and achievable for readers of all levels.